DST-01/HDST-02/VFM-3A

Differential Sticking Tester

Summery

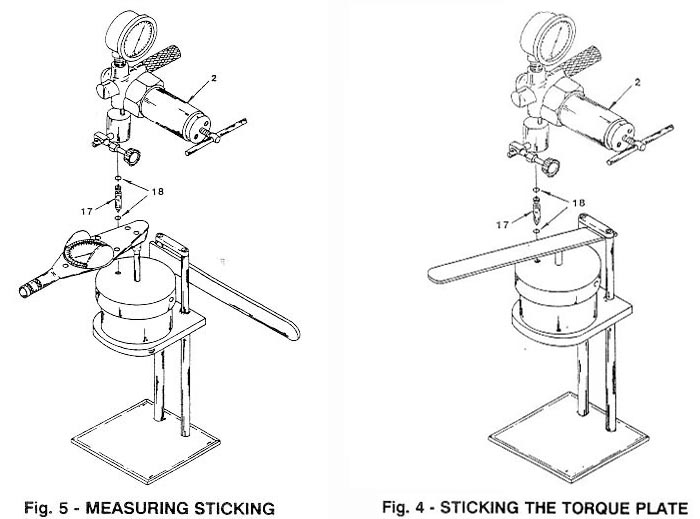

The Differential Sticking Tester was designed to determine how likely a given drilling fluid will be to produce a stuck pipe situation and how effective a given drilling fluid treatment or application of spotting fluid in any given drilling fluid would be in reducing this tendency. This measurement is called the Stuck Tendency Coefficient. It takes into account both the stickiness and the cake building capability of the drilling fluid. The Stuck Tendency Coefficient is determined by the Timed Filtrate Test.

The use of the optional yoke attachment along with the radius’d torque plate allows a measurement called Bulk Sticking Coefficient to be obtained. By measuring the area of caking using a controlled cake thickness during the test, the Bulk Sticking Coefficient is obtained. The Bulk Sticking Coefficient is determined by the Fixed Cake Thickness Test.

Differential sticking may be identified by the following characteristics

1. Pipe sticks after remaining motionless for a period of time

2. Pipe cannot be rotated or moved when circulation is maintained

Specifications

| Part No. | Model | Description &Technical Parameters | Remarks |

| 150-50 | DST-01 | Stainless steel vessel of approximately 200 mL | |

| Working Pressure :477.5 psig (3,291 kPa) | |||

| Size: 6.5" × 6" × 18" (16.5 × 15 × 46 cm) | |||

| Weight: 30lb (14 kg) | |||

| 150-55 | HDST-02 | Working Pressure: 477.5 psig (3,291 kPa) | |

| Working Temperature: up to 170℃ (340℉) | |||

| Size: 13.8" × 23.6" × 18" (35 × 50 × 60 cm) | |||

| Weight: 77lb (35 kg) | |||

| 151-60 | VFM-3A | Power supply:220V 50HZ | |

| Turnover speed:5.5-6.5minutes/round | |||

| Digital display of the Angle reading | |||

| Accuracy:0.5% | |||

| Size:14.6" × 9.3" × 9.3" (35 × 21 × 21 cm) | |||

| Weight :13 lb. (6 kg) |