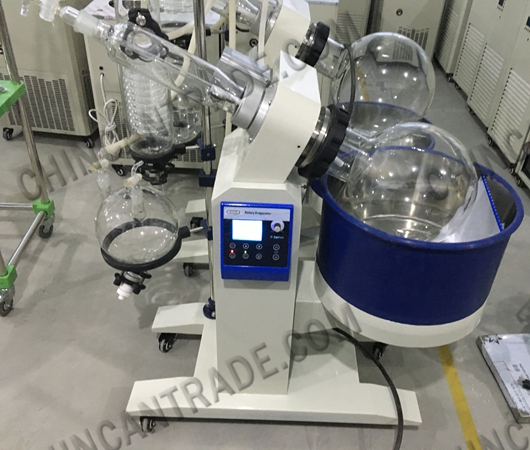

ZR1010/ZR1020

Rotary Evaporator

Summary:

Rotary evaporator is mainly used in pharmaceutical, chemical and bio-pharmaceutical industry concentration, crystallization, drying, separation and dissolution of coal recovery.

The principle is: under vacuum conditions, constant temperature heating, constant speed rotation of the rotating bottle, the bottle wall materials in a large-area film formation, the evaporation efficiency.

Coal solvent evaporation through efficient glass condenser cooling, recovered in the collection bottle, greatly improving the efficiency of evaporation. Especially for high temperature easily decomposed denatured concentrated biological purification items.

Feature:

- Use of PTFE and rubber composite seal can maintain a high degree of vacuum.

- Ensure efficient use of the condenser high recovery.

- Rotating bottle coupling nut for easy loading and unloading.

- Collection bottle under the mouth is equipped with a piston, coal solvent recovery is very fast.

- Continuous feed.

- Vacuum system installed vacuum table, choose the best material for a low-boiling working vacuum.

- Water bath digital thermostat control, and up and down.

- Reasonable structure, material stress, a lot of mechanical structures made of stainless steel and aluminum parts.

- Glass blocks all with high temperature and high boron glass, the key electrical parts imports.

- Easy rubber seal used in all new national standard, user-friendly purchasing replacement.

Specification:

| Model | ZR1010 | ZR1020 |

| Rotary Bottle(L) | 10 | 20 |

| Collecting Bottle(L) | 5 | 10 |

| Motor Power(W) | Brushless250 | Brushless250 |

| Rotary speed(rpm) | 20-130 | 20-130 |

| Overall power(KW) | 4.8 | 6.3 |

| Power supply | Simplex220V/50HZ | Three Phase220V/380V/50HZ |

| Bath temperature range(℃) | Room temp-99/Room temp-299 | Room temp-99/Room temp-299 |

| Sealing method | PTFE seal | |

| Vacuum degree | -0.098Mpa | -0.098Mpa |

| Elevating function | Electric elevation | Electric elevation |

| Dimensions(mm) | 920*550*1700 | 1250*600*2100 |

Pictures of real products