R5006KB

Rotary Evaporator

In Pilot Production Evaporating Field

With our unique tandem receiving technology, Solvent Discharge no longer need to stop evaporation process, to release and repump system vacuum. The technology allows real continuous work without vacuum wave, which obviously increases productivity, simplifies system receiving structure and improves sealing performance. (for K series)

Features

1. PTFE Charging Valve

New structure and material applied, is able to offer purely clean charging process and durable use experience.

2. Flange Quick Press Ring

One-piece quick clip design. Offer new experience on easy, reliable, and high sealing connection for flanges (no tools required).

3. PTFE Cork (Patent No. 01253089.1)

Patent structure. Cork is anti-corrosion, no vacuum grease, no pollution to solvent received.

.png)

4. Anti-corrosion & Wearable Sealing System

Specially designed and precisely manufactured. Enable system ultimate vacuum rate reaching 133Pa. 90% users do not need to replace rotary seal in one year.

5. Ex-proof Modification (Optional)

Offer EX proof upgrade on Motor, Control Boxes of rotation and heating, Wiring, and Safety measures per user needs. Ex level reaches ExdIIBT4.

6. Bumping Tube (Optional)

Preventing unexpected solution bumping into receiving flask.

7. Cold Trap Protection (Optional)

Trapping escaped corrosive/harmful vapor so to protect vacuum pump and people health. Avoid vacuum pump liquid flow back to system.

8. Flask Unload Handler (Optional)

Specially designed for handling and unloading big capacity evaporating flask, is one useful and popular optional tool.

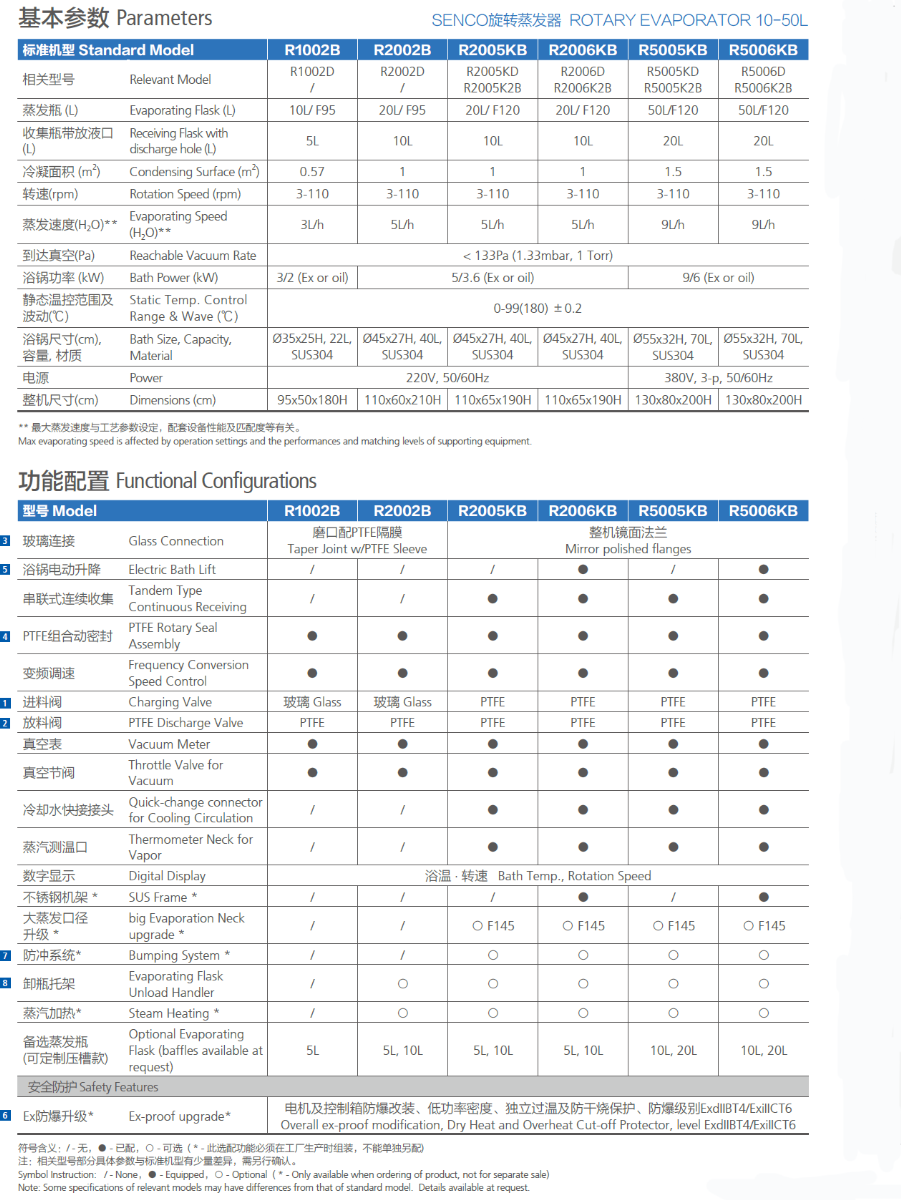

Specifications