CW50

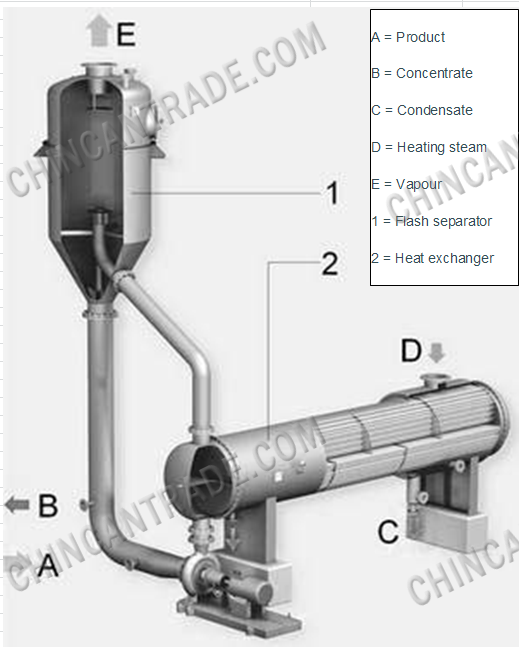

Forced(self)circulation evaporator

Summary

——Design

Horizontal or vertical shell-and-tube heat exchanger or plate heat exchanger, with flash vessel/separator and circulation pump.

——Operation

The liquid is circulated through the heat exchanger by means of a circulation pump, where it is superheated at an elevated pressure, higher than its normal boiling pressure. When entering the separator, the pressure in the liquid is rapidly reduced resulting in some of the liquid being flashed, or rapidly boiled off.

Since liquid circulation is maintained, the flow velocity in the tubes and the liquid temperature can be controlled to suit the product requirements of the pre-selected temperature difference.

——Particular features

Less foul – boiling/evaporation will not take place on the heating surfaces, but in the separator. Fouling due to incrustation and precipitation in the calandria is therefore minimised.

Optimised heat exchange surface – flow velocity in the tubes determined by the circulation pump.

——Fields of application

Liquids with a high tendency for fouling, highly viscous liquids, as the high concentration step in multiple-effect evaporation plants.

Forced circulation evaporators are suited as crystallising evaporators for saline solutions.

Specifications

| COMMODITY AND SPECIFICATION | MODEL | SPECIFICATION |

| Forced circulation evaporator | CW50 |

Forced(self)circulation evaporator Distiller & Fittings 1-Evaporation chamber(Stainless steel 304 ) Volume 50L Capacity: 60-80L/hour( ethanol) 2- Heat exchanger(Stainless steel 304 ) Heat transfer area:0.5m2 Mode:Vertical,Raw material’s vapor in tube, hot oil in shell Heating Type: heat conduction oil 3- Condenser (Stainless steel 304 ) Heat transfer area:1.5m2 Mode:Horizontal,Raw materials vapor in shell, Cooling water in tube 4- Receiver(Stainless steel 304 ) Volume 50L 5- Temperature measuring devices ( Evaporation chamber\Evapor) ), Honeywell Type:DC1040CT-201-00B-E Control form:PID 6-Electrical control cabinet 0.5KW 220V-50/60Hz single phase Basic size:500*400*200mm Wire requirement: More than 2.5 square single-core wire |

| VACUUM SYSTEM C | OPTIONAL |

No-load ultimate vacuum pressure 50mbar Pump:water-jet pump Exhaust rate: 10L/min*4 Motor power: 0.18KW 220V-50/60Hz single phase or 110v-60Hz single phase Szie : 385*280*420mm(L*W*H)11KG |

| ElECCTRIC OIL HEATING UNIT | OPTIONAL |

Electric oil heating unit- Power 16~24KW Temperature:Room temp ~190℃ Temperature accuracy:±1℃ |

| PIPE INSULATION SYSTEM | OPTIONAL |

Include: 1- Heat tracing tape for outlet sections (Heavy braided glass yarn covering. Easily applied & removed. Power:0.5KW 220V-50/60Hz ) 2-Temperature control instrument (XMT-E9000 :K-type thermocouple PID) |

| FRAME | OPTIONAL |

Material:Carbon steel Q235B, 1500*600*1700mm(L*W*H)300KG |

Primary evaporation: Model: CW Series & CF Series: Designed for material ethanol content >90%

Extraction Pretreament: Model: BML Series: Designed for material ethanol content: 5%~10%

Extraction : Model:DZL Series : Designed for material ethanol content: <1%