DPS

Air Cooled Dry Screw Vacuum Pump

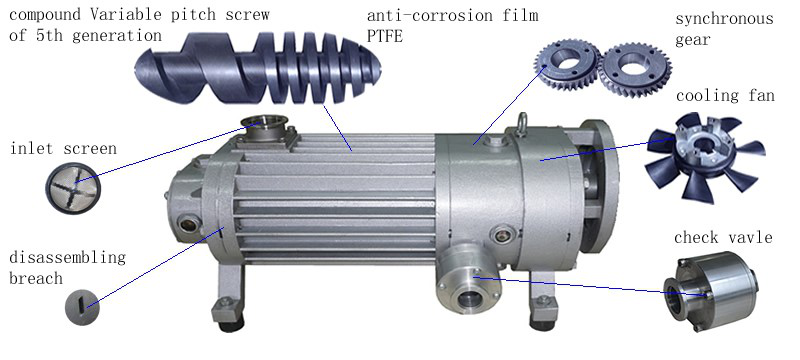

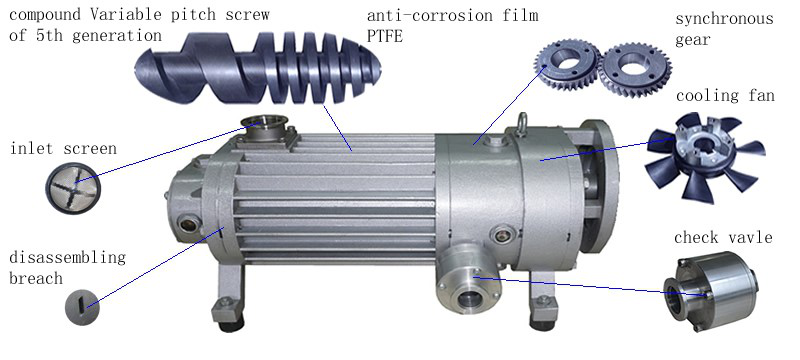

First Air Cooled Dry Variable Pitch Screw Vacuum Pump:

DPS dry compound screw vacuum pump is innovation and development of AfaPa’s products, using of the fifth generation of compound variable pitch screw technology (30% energy saving, low exhaust temperature), with high efficiency, energy saving, environmental protection, lightweight, easy operation, reliable performance characteristics. It’s a main trend of the vacuum pump.

Applications:

Dry compound screw vacuum pump is ideal for any application where oil contamination is unacceptable and for corrosive field. Dry screw vacuum pump widely used in the fields of medical instruments, analysis instruments, biological products and pharmaceutical preparation, food and medicine packaging, gasoline vapor recycle, film preparation, high science engineering and chemical analysis, semiconductor, micro-electronics, solar energy, deal with materials industrial and R&D labs etc.

Technical Specifications:

|

Model |

DPS020 |

DPS050 |

DPS080 |

|

Pumping Speed(m3/h) |

20 |

50 |

80 |

|

Ultimate Vacuum(Pa) |

3(50) |

|

Motor Power(Kw/Hp) |

1.1/1.5 |

1.5/2.0 |

2.2/3.0 |

|

Motor Speed(Rpm) |

2900 |

|

Inlet Hole |

KF25 |

KF40 |

KF40 |

|

Outlet Hole |

KF25 |

KF25 |

KF25 |

|

Cooling Method |

Air Cooled |

|

Gear/Bearing Lubrication |

100# Synthetic Gear Oil |

|

Sealing Method |

Double Lip Teflon /Double Lip Rubber/Mechanical Seal |

|

Noise(dB) |

69 |

70 |

71 |

|

Weight(Kg) |

36 |

53 |

62 |

Original Designs and Innovations:

Features:

1.Advanced technology, adopting advanced the fifth generation of compound variable pitch screw technology.

2.Environmental friendly, environment protection, no-oil (oil free), no-water, non-pollution, clean vacuum.

3.The gases pumped can be recycled, applying for oil and gas recovery and solvent recycling and special gas recycling.

4.Energy-saving, energy-saving technology with variable pitch, reduce energy consumption by 30%.

5.Chemical corrosion resistance, having anti-corrosion film PTPE.

6.Air-cooled structure, easy to operate.

7.High ultimate vacuum up to 3Pa.

8.Operating pressures from atmospheric pressure to ultimate pressure.

9.Saving manpower, longer maintenance intervals of up to ten thousand hours.

10.Easy to clean, if the pump under the dirt can be filled with the gas or cleaning agent to cleaning.

11.Reliable sealing structure, use of a lip seal, mechanical seal and a gas seal structure, exhaust smooth, with good fluid-handling capabilities.

12.Light weight, using new lightweight materials.

13.Low voice and vibration, using high precision parts.

14.Low temperature rise, due to the use the new material, and heat faster.

15.Shockproof prevent design can be placed on the ground directly.

16.Disassembling break, easy to maintain.

17.Easy to install, adopting KF connection.

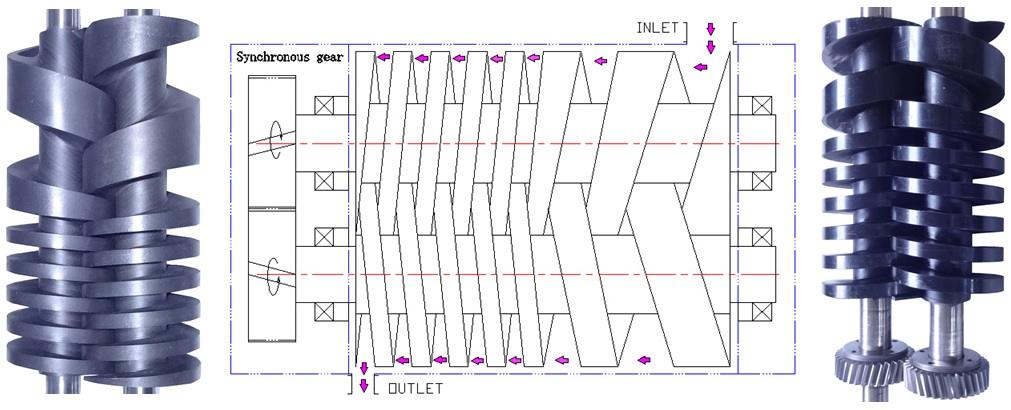

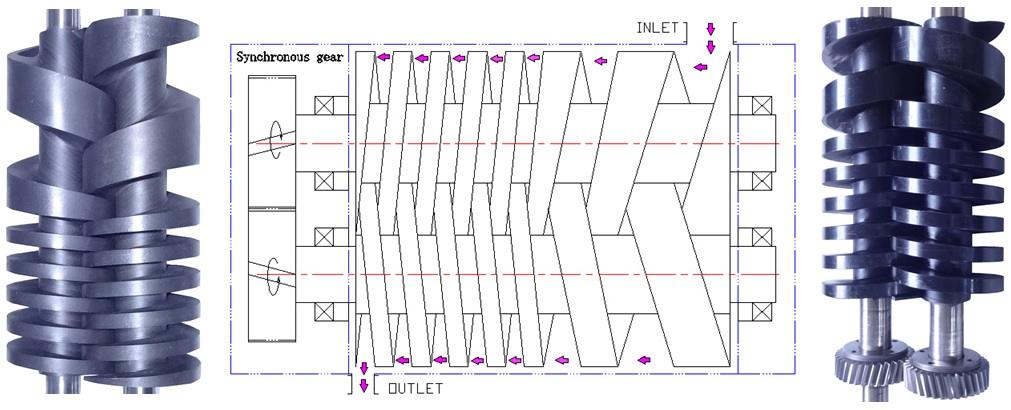

Principle:

Dry Compound Screw Vacuum Pump are consist of two paralleled screw rotors and pump body form multiple sealed space, rotor and rotor, rotor and pump body all keep minuscule clearance(no touch, no friction), with the reverse gears driving, gas keep continuous transfer from inlet hole to outlet hole. Due to two rotors and pump body have no friction each other, need not lubrication oil, can keep clean gas. Gas keep continuous transfer, short passageway, high efficiency, outlet hole position lower than screw rotors, strong drainage ability, easy to cleaning, no intermediate bulkhead(claw vacuum pump and rotors vacuum pump have intermediate bulkhead), better exhaust and drainage, easy to maintain.

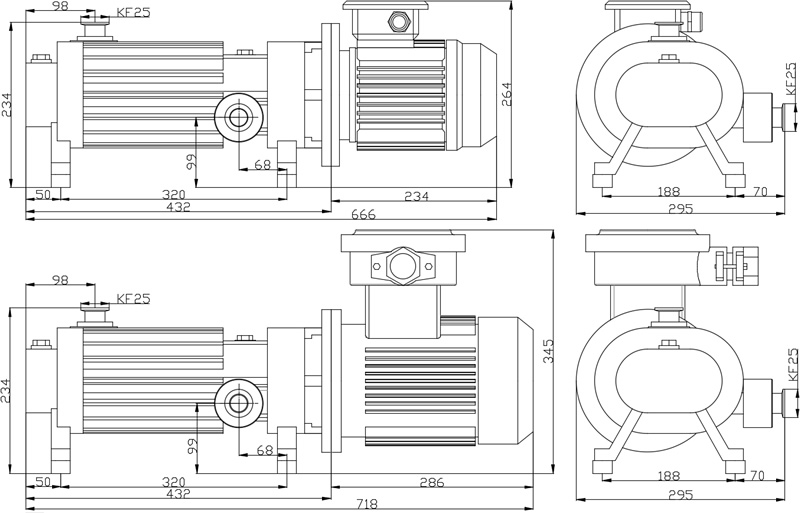

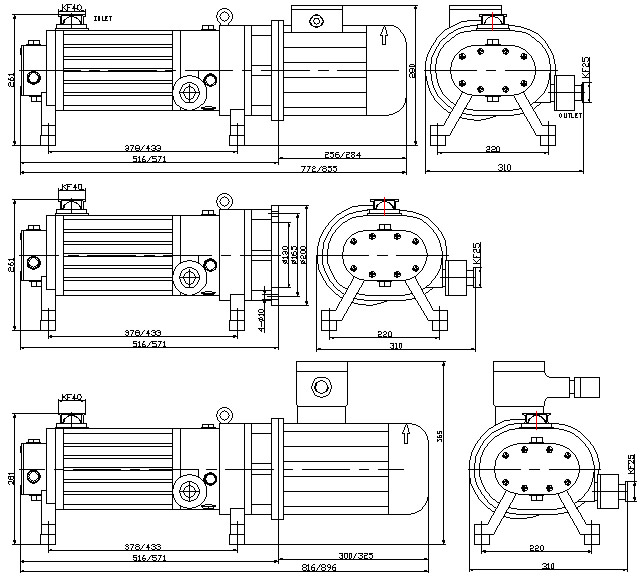

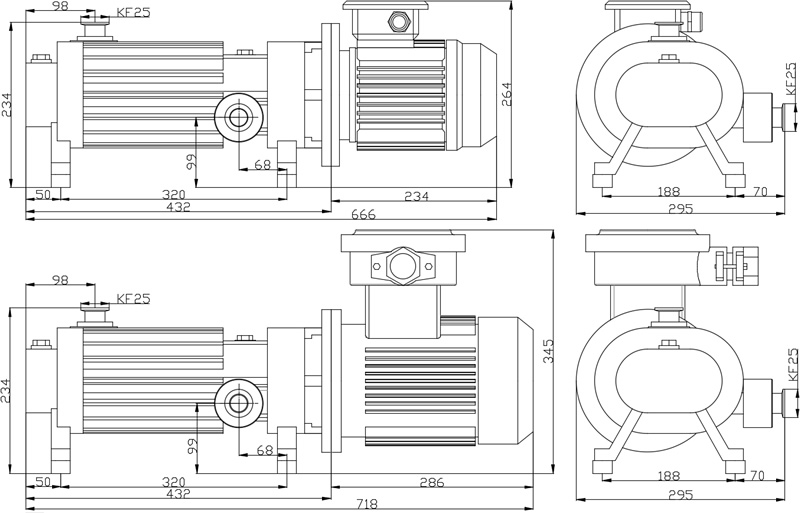

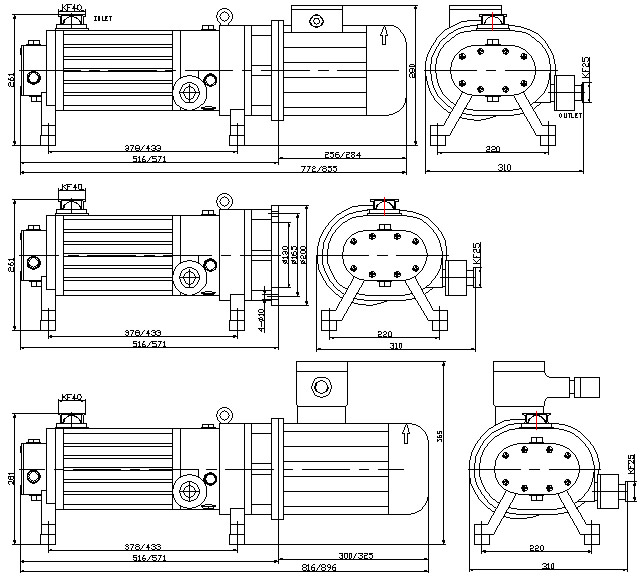

Dimensions:

DPS20 Motor/Ex Motor

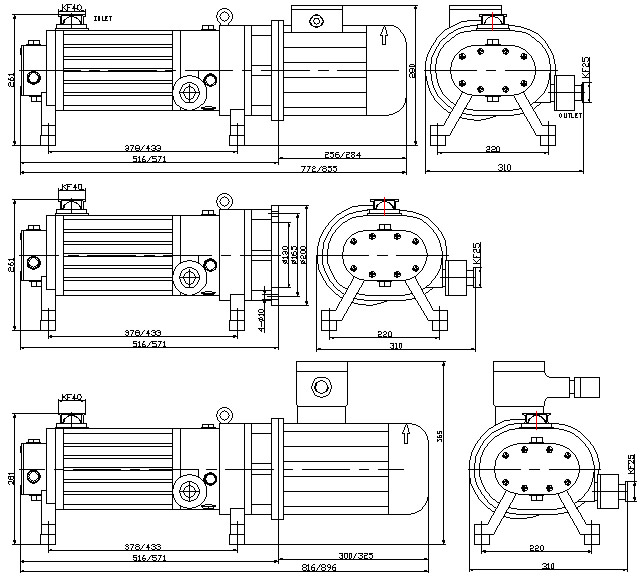

DPS50/80 Motor/Ex Motor

First Air Cooled Dry Variable Pitch Screw Vacuum Pump:

DPS dry compound screw vacuum pump is innovation and development of AfaPa’s products, using of the fifth generation of compound variable pitch screw technology (30% energy saving, low exhaust temperature), with high efficiency, energy saving, environmental protection, lightweight, easy operation, reliable performance characteristics. It’s a main trend of the vacuum pump.

Applications:

Dry compound screw vacuum pump is ideal for any application where oil contamination is unacceptable and for corrosive field. Dry screw vacuum pump widely used in the fields of medical instruments, analysis instruments, biological products and pharmaceutical preparation, food and medicine packaging, gasoline vapor recycle, film preparation, high science engineering and chemical analysis, semiconductor, micro-electronics, solar energy, deal with materials industrial and R&D labs etc.

Technical Specifications:

|

Model |

DPS020 |

DPS050 |

DPS080 |

|

Pumping Speed(m3/h) |

20 |

50 |

80 |

|

Ultimate Vacuum(Pa) |

3(50) |

|

Motor Power(Kw/Hp) |

1.1/1.5 |

1.5/2.0 |

2.2/3.0 |

|

Motor Speed(Rpm) |

2900 |

|

Inlet Hole |

KF25 |

KF40 |

KF40 |

|

Outlet Hole |

KF25 |

KF25 |

KF25 |

|

Cooling Method |

Air Cooled |

|

Gear/Bearing Lubrication |

100# Synthetic Gear Oil |

|

Sealing Method |

Double Lip Teflon /Double Lip Rubber/Mechanical Seal |

|

Noise(dB) |

69 |

70 |

71 |

|

Weight(Kg) |

36 |

53 |

62 |

Original Designs and Innovations:

Features:

1.Advanced technology, adopting advanced the fifth generation of compound variable pitch screw technology.

2.Environmental friendly, environment protection, no-oil (oil free), no-water, non-pollution, clean vacuum.

3.The gases pumped can be recycled, applying for oil and gas recovery and solvent recycling and special gas recycling.

4.Energy-saving, energy-saving technology with variable pitch, reduce energy consumption by 30%.

5.Chemical corrosion resistance, having anti-corrosion film PTPE.

6.Air-cooled structure, easy to operate.

7.High ultimate vacuum up to 3Pa.

8.Operating pressures from atmospheric pressure to ultimate pressure.

9.Saving manpower, longer maintenance intervals of up to ten thousand hours.

10.Easy to clean, if the pump under the dirt can be filled with the gas or cleaning agent to cleaning.

11.Reliable sealing structure, use of a lip seal, mechanical seal and a gas seal structure, exhaust smooth, with good fluid-handling capabilities.

12.Light weight, using new lightweight materials.

13.Low voice and vibration, using high precision parts.

14.Low temperature rise, due to the use the new material, and heat faster.

15.Shockproof prevent design can be placed on the ground directly.

16.Disassembling break, easy to maintain.

17.Easy to install, adopting KF connection.

Principle:

Dry Compound Screw Vacuum Pump are consist of two paralleled screw rotors and pump body form multiple sealed space, rotor and rotor, rotor and pump body all keep minuscule clearance(no touch, no friction), with the reverse gears driving, gas keep continuous transfer from inlet hole to outlet hole. Due to two rotors and pump body have no friction each other, need not lubrication oil, can keep clean gas. Gas keep continuous transfer, short passageway, high efficiency, outlet hole position lower than screw rotors, strong drainage ability, easy to cleaning, no intermediate bulkhead(claw vacuum pump and rotors vacuum pump have intermediate bulkhead), better exhaust and drainage, easy to maintain.

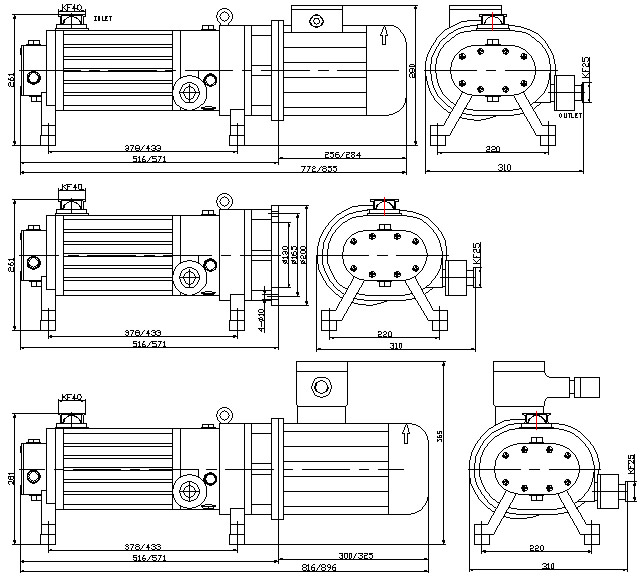

Dimensions:

DPS20 Motor/Ex Motor

DPS50/80 Motor/Ex Motor